- Home

- Company

-

Products

Warehousing Solutions

-

Selective Pallet

Racking - Drive in Racking

- Combination Rack

Static Racking

- Multi-Tier

- Shelving Racks

- Mobile Shelving

Shelving Solutions

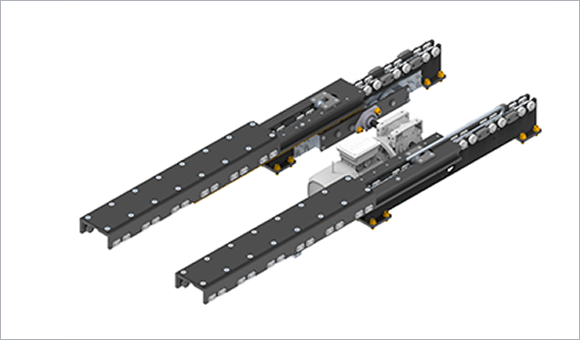

- Shuttle Racking

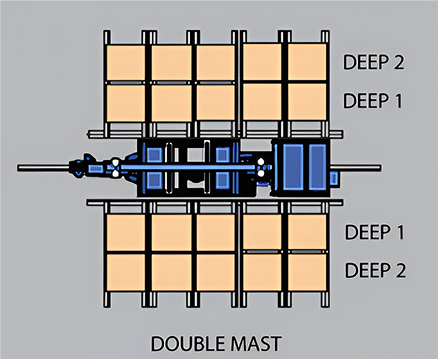

- Mobile Racking

- Pallet Flow Racking

Dynamic Racking

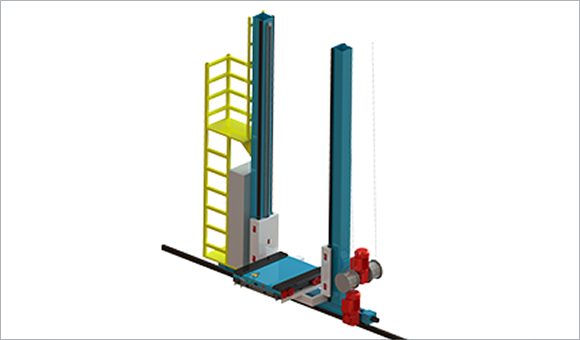

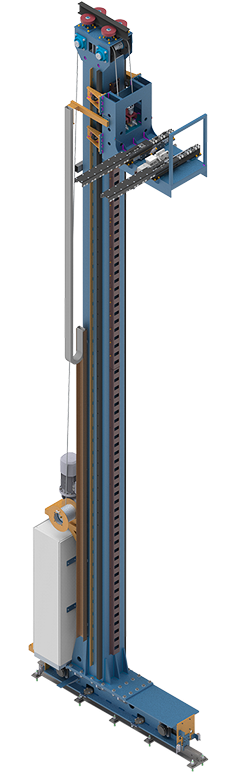

- Stacker Crane ASRS

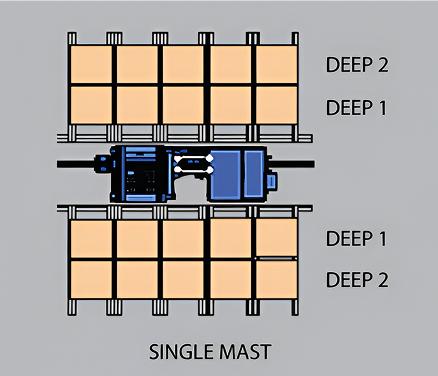

- Mother Child Shuttle ASRS

- Mini Load ASRS

Automated Racking

- Mezzanine Floors

- Cantilever Racking

Long Span Racking

Industrial Storage System & Office Furniture

- Tool Cabinet

- Tool Trolly

Tool Storage

-

Industrial Computer

Cabinet -

Press Brake

Bending Tool -

Vertical Pull Out

Cabinet

Industrial Cabinet

-

Perfo Cabinet with

Hinged Door - Storage Cupboard

- Machine Side Cabinet

Industrial Cupboard

- Platform Trolley

- Bin Trolley

- Ladder Trolley

Industrial Trolley

- Utility Rack

- FIFO Rack

Storage Rack

-

Optimize Storage

Rack-Push Pull Type -

Optimizer Mobile

Storage System

Optimizer Mobile Storage System

Automated Storage Solution

Roll - Out Storage Solution

-

Selective Pallet

- Career

- Contact

-

×

×Warehousing solutions

Please fill the details

×Warehousing solutions

Please fill the details

×Warehousing solutions

Please fill the details

×Warehousing solutions

Please fill the details

×Smart Storage Solution

Please fill the details